|

|

11-20-2017, 03:52 PM

11-20-2017, 03:52 PM

|

#21

|

Rivet Master

2007 22' International CCD

Corona

, California

Join Date: Jul 2013

Posts: 9,180

|

Quote:

Originally Posted by slowmover

Cat Scale to Cat Scale. With the phone app and separate locator, it's easy. Second weighs up to dozens are $2/ea.

|

Gives you an accurate set of measurements that one time, requires a rather big bit of infrastructure. Was looking for a self-contained method that does not require external infrastructure or equipment that can be carried as part of the vehicle. CAT scale would be perfect for calibration of an add-on system, though.

Strain gauges can be accurate, repeatable and reliable, but take a lot of signal conditioning hardware to do it right.

Had considered either ultrasonic or laser distance measuring hardware looking at suspension squat at one point, all talking to an Arduino or other small processor system.

Other thoughts?

__________________

Rich, KE4GNK/AE, Overkill Engineering Dept.

'The Silver HamShack' ('07 International 22FB CCD 75th Anniversary)

Multiple Yaesu Ham Radios inside and many antennae sprouting from roof, ProPride hitch, Prodigy P2 controller.

2012 shortbed CrewMax 4x4 Toyota Tacoma TV with more antennae on it.

|

|

|

11-20-2017, 06:30 PM

11-20-2017, 06:30 PM

|

#22

|

Rivet Master

Currently Looking...

Vancouver

, British Columbia

Join Date: Oct 2012

Posts: 4,592

|

Quote:

Originally Posted by rmkrum

Part of the initial thinking is to come up with a reliable method to measure suspension loading on the TV, which might give an indication of weight transfer. I have my doubts on making this kind of measurement in motion, because of noise induced by the motion and road surface, but if there is a reliable way of measuring suspension height at low speed, that could give a number for processing an initial jack adjustment at rest.

Any ideas?

|

Seems to me the starting point would be suspension height measurement using OE sensors. My last few vehicles all had this (one sensor front, one sensor rear) as part of the standard headlight aiming system. A simple linkage on the hub, connected by a mechanical link to a rotational sensor, processed to dynamically adjust headlight angle. Same system was used if the vehicle had one axle or two axle air suspension. Proven technology.

Vehicle height at each axle relative to baseline position would go a long way to finding that sweet spot, IMO.

On heavy equipment (mining trucks) we had gas strut pressure to measure tire load for detection of overloading. Real time payload reading was on a dash readout, and transmitted to fleet maintenance manager, and on an external display for the loader operator.

I’d keep it simple.

Cool thread.

Jeff

|

|

|

11-20-2017, 07:43 PM

11-20-2017, 07:43 PM

|

#23

|

|

Wise Elder

2010 30' Classic

Vintage Kin Owner

South of the river

, Minnesota

Join Date: Dec 2009

Posts: 4,169

|

Quote:

Originally Posted by rmkrum

It has been noted that using power tools on the WD jacks tends to shear a pin in the head of the jack, so I usually use the ProPride-supplied manual ratchet wrench to make the adjustment. My DeWalt impact driver is really, really good at over-torquing things at the slightest provocation...

|

I used to use a (non-impact) battery operated cordless drill on mine but concluded that it was overall better to use the crank that came with my trailer (for the stabilizers) because I didn't have to deal with charging the drill battery and I didn't have to worry about it being stolen.

Sean (at ProPride) had experimented with motorized jacks back in 2009 or 2010, using the motor heads that fit the stablizers we use, and has never turned it into a product. Everyone's situation is different, I guess, but I think I'll stick with the crank until I'm too old to turn it.

The crank is a huge improvement over that ratchet that comes with the pp.

Once I got my setup dialed in I marked it with paint and always use that. I do not find that the wind, load, phase of the moon, barometric pressure, tire size, octane rating of fuel used, or density altitude actually affect WD bar rigging in any meaningful way.

Quote:

|

Typically, I set the jacks to what worked last time, and set out on the highway. At about 55 MPH (in California) I experience a bit of porpoising because of inadequate WD jack tension. I find a place to pull over, adjust the jacks by hand, and set out again, accelerating to the speed limit again. It still porpoises. Pull over again, adjust again, rinse and repeat until it's stable. (yeah, I know about measuring wheel well height on the front end of the TV during setup. Looking for porpoising works better for me when trailer load-out and TV bed load varies)

|

There isn't a "too tight." Once you figure out how much to crank them in poor conditions, use that, you're good.

__________________

To learn to see below the surface, you must adjust your altitude

|

|

|

11-20-2017, 08:19 PM

11-20-2017, 08:19 PM

|

#24

|

Rivet Master

2007 22' International CCD

Corona

, California

Join Date: Jul 2013

Posts: 9,180

|

Quote:

Originally Posted by jcl

Seems to me the starting point would be suspension height measurement using OE sensors. My last few vehicles all had this (one sensor front, one sensor rear) as part of the standard headlight aiming system. A simple linkage on the hub, connected by a mechanical link to a rotational sensor, processed to dynamically adjust headlight angle. Same system was used if the vehicle had one axle or two axle air suspension. Proven technology.

Vehicle height at each axle relative to baseline position would go a long way to finding that sweet spot, IMO.

On heavy equipment (mining trucks) we had gas strut pressure to measure tire load for detection of overloading. Real time payload reading was on a dash readout, and transmitted to fleet maintenance manager, and on an external display for the loader operator.

Iíd keep it simple.

Cool thread.

Jeff

|

Jeff, any idea what kind of rotational sensor? Manufacturer, or vehicle make and model to try for some clues?

I agree, the simpler the better, and if itís automotive hardware, more likely to survive the experience.

__________________

Rich, KE4GNK/AE, Overkill Engineering Dept.

'The Silver HamShack' ('07 International 22FB CCD 75th Anniversary)

Multiple Yaesu Ham Radios inside and many antennae sprouting from roof, ProPride hitch, Prodigy P2 controller.

2012 shortbed CrewMax 4x4 Toyota Tacoma TV with more antennae on it.

|

|

|

11-20-2017, 08:20 PM

11-20-2017, 08:20 PM

|

#25

|

Rivet Master

2012 27' Flying Cloud

W

, New England

Join Date: Oct 2012

Posts: 7,402

|

Jammer - I'm tempted to take your "octane" quote over to the argue thread! 🤣🤣🤣

Well played!

|

|

|

11-20-2017, 08:29 PM

11-20-2017, 08:29 PM

|

#26

|

Rivet Master

2007 22' International CCD

Corona

, California

Join Date: Jul 2013

Posts: 9,180

|

Quote:

Originally Posted by Jammer

I used to use a (non-impact) battery operated cordless drill on mine but concluded that it was overall better to use the crank that came with my trailer (for the stabilizers) because I didn't have to deal with charging the drill battery and I didn't have to worry about it being stolen.

Sean (at ProPride) had experimented with motorized jacks back in 2009 or 2010, using the motor heads that fit the stablizers we use, and has never turned it into a product. Everyone's situation is different, I guess, but I think I'll stick with the crank until I'm too old to turn it.

The crank is a huge improvement over that ratchet that comes with the pp.

Once I got my setup dialed in I marked it with paint and always use that. I do not find that the wind, load, phase of the moon, barometric pressure, tire size, octane rating of fuel used, or density altitude actually affect WD bar rigging in any meaningful way.

There isn't a "too tight." Once you figure out how much to crank them in poor conditions, use that, you're good.

|

I suspect, without some care in adjusting WD it could be possible to overload the front axle or stiffen the WD too much for a comfortable ride or screw up rear axle traction.

__________________

Rich, KE4GNK/AE, Overkill Engineering Dept.

'The Silver HamShack' ('07 International 22FB CCD 75th Anniversary)

Multiple Yaesu Ham Radios inside and many antennae sprouting from roof, ProPride hitch, Prodigy P2 controller.

2012 shortbed CrewMax 4x4 Toyota Tacoma TV with more antennae on it.

|

|

|

11-20-2017, 09:41 PM

11-20-2017, 09:41 PM

|

#27

|

4 Rivet Member

2007 27' Classic FB

Fredericksburg

, Texas

Join Date: Jun 2011

Posts: 300

|

Sean said that once you get to 8 inches of lift you won't be shifting much more weight onto the front wheels. So, that should be a limiting factor.

__________________

The Tex-i-can is Ready to Camp

|

|

|

11-20-2017, 09:58 PM

11-20-2017, 09:58 PM

|

#28

|

Rivet Master

2007 22' International CCD

Corona

, California

Join Date: Jul 2013

Posts: 9,180

|

Propride Power WD engineering

Ah, that was one of the numbers I was looking for. Now I can get a critical part of the limit switch setup designed. I was guessing at 8 inches after the bars get seated. On my rig itís probably a total of about 9 inches from jacks bottomed out. Sometimes I do go all the way down to disconnect properly.

Thanks for the information!

__________________

Rich, KE4GNK/AE, Overkill Engineering Dept.

'The Silver HamShack' ('07 International 22FB CCD 75th Anniversary)

Multiple Yaesu Ham Radios inside and many antennae sprouting from roof, ProPride hitch, Prodigy P2 controller.

2012 shortbed CrewMax 4x4 Toyota Tacoma TV with more antennae on it.

|

|

|

11-20-2017, 10:31 PM

11-20-2017, 10:31 PM

|

#29

|

Rivet Master

1972 31' Sovereign

1975 31' Excella 500

Currently Looking...

Benton

, Arkansas

Join Date: Mar 2013

Posts: 5,868

|

Quote:

Originally Posted by rmkrum

I think getting the jack height is fairly straightforward, just accurately count the turns cranked into the jacks by the motors. There is a cross shaft that couples both jacks, so the count only had to be done on one side. Load sensors get expensive for high accuracy, but I haven;t looked in that direction much yet.

The first step, IMHO, is gaining repeatably in the initial settings, and a turn count is the easy way. A magnet and a reed switch buys you that if you start from a known point, and a lower limit switch gets the 'zero' height you can start with. Just count from there knowing the direction you are driving the motor... Or use a slotted wheel and two photo pickups in quadrature. Then you can figure out the count and direction if it wanders or rolls back.

|

There is no doubt that this could be done with a load cell installed between weight bearing parts on a hitch or suspension. I think load cell reliability might be a problem though.

__________________

The fact that I am opinionated does not presuppose that I am wrong......

|

|

|

11-20-2017, 11:03 PM

11-20-2017, 11:03 PM

|

#30

|

Rivet Master

Currently Looking...

Vancouver

, British Columbia

Join Date: Oct 2012

Posts: 4,592

|

Quote:

Originally Posted by rmkrum

Jeff, any idea what kind of rotational sensor? Manufacturer, or vehicle make and model to try for some clues?

I agree, the simpler the better, and if it’s automotive hardware, more likely to survive the experience.

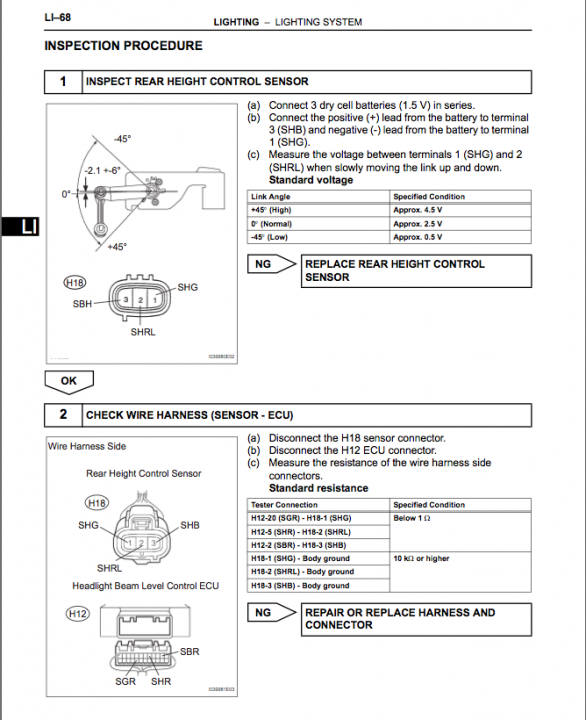

|

My BMW models have used a variety of sensors, all along the same lines. They only differ in mounting fixtures. My current vehicle is a 2007 X3 3.0si. My X5 (2003) had similar sensors, as did other BMW cars I owned.

If you do a google image search on BMW Headline level sensor you will see many variants.

I know other manufacturers use similar sensors. Landrover sensors look similar, for the air suspension. Given your tow vehicle, I looked up Toyota and found a similar product on the Tacoma. They use the same sensor on the Tacoma, Prius, Lexus, and Mazda RX8.

Also search on Delphi, as they appear to be one of the suppliers.

These sensors are generally designed and built to survive mounted to the chassis near the suspension control arms. Simpler ones will return a variable voltage. Some may use a more complicated signal, given the multiplexed wiring on some modern vehicles (including BMW).

Here is a Toyota one from an aftermarket supplier. I have no experience with the quality of this one. I do know that the BMW ones have never failed me over the past few decades.

https://www.amazon.com/Guteauto-Head.../dp/B071GCW2MM

I know they react fairly quickly, as I have active headlights, and can watch them go both left/right and up/down based on steering rack position, and these sensors.

I think the lightness in the tow vehicle steering is entirely due to front axle unloading, and that a position sensor would be accurate enough to indicate how much WD to restore front axle loading. Combined with a rear sensor it could be set up to return the tow vehicle to level, just as it does with air suspension, but using WD jacks. Set it in a parking lot, pull ahead several lengths and confirm, and then don't have it set to automatically adjust when in motion (just my $0.02).

Jeff

|

|

|

11-20-2017, 11:31 PM

11-20-2017, 11:31 PM

|

#31

|

Rivet Master

2007 22' International CCD

Corona

, California

Join Date: Jul 2013

Posts: 9,180

|

Propride Power WD engineering

Hm. Has possibilities. Any data on how it works, wiring, etc? Good point about shutting off the automatics at some very low speed once itís set.

I agree about front axle lightness being primarily due to unloading. Have had it happen on other vehicles I have grossly overloaded in the rear. Lifted the front of a Volvo sedan almost 4 inches by stacking a pile of pallets on the trunk lip. Long stupid story. Had to talk wife into riding to help keep front end down. Was an Ďinteresting tripí. Thatís one of the ways I learned about the feeling of loss of control without enough proper weight distribution. The Volvo wandered a lot at 35 MPH...

__________________

Rich, KE4GNK/AE, Overkill Engineering Dept.

'The Silver HamShack' ('07 International 22FB CCD 75th Anniversary)

Multiple Yaesu Ham Radios inside and many antennae sprouting from roof, ProPride hitch, Prodigy P2 controller.

2012 shortbed CrewMax 4x4 Toyota Tacoma TV with more antennae on it.

|

|

|

11-20-2017, 11:52 PM

11-20-2017, 11:52 PM

|

#32

|

Rivet Master

Currently Looking...

Vancouver

, British Columbia

Join Date: Oct 2012

Posts: 4,592

|

Here it is mounted on a BMW 5 series sedan.

Earlier models show a three wire connection, not sure about later models. The diagnostic test for a similar sensor (Prius) is as follows.

I would look up your specific vehicle and see if there was an option for level sensing, whether for Xenon headlights (a usual application, because they can blind oncoming drivers) or for air suspension. I see sensors listed in parts manuals for Tacoma models, just not sure what years/configurations/options had them.

Jeff

|

|

|

11-21-2017, 12:24 AM

11-21-2017, 12:24 AM

|

#33

|

Rivet Master

Currently Looking...

Vancouver

, British Columbia

Join Date: Oct 2012

Posts: 4,592

|

2012 Tacoma parts book does not list this sensor, but it was used up until 2008, which I understand is the same chassis.

One part number reference shows as Toyota part 89407-48020

One manufacturer site: https://www.dormanproducts.com/p-72313-924-755.aspx

Will-fit versions are $27 each on Amazon. Not sure about quality.

|

|

|

11-21-2017, 04:50 AM

11-21-2017, 04:50 AM

|

#34

|

2 Rivet Member

2016 30' Classic

Lexington

, Kentucky

Join Date: Aug 2016

Posts: 48

|

My experience with Power PP jacks

Hey guys, I thought I would chime in about the power pp jacks. The first set I made was in March 2016 and have used it since then. The short answer is they have been 100% reliable and if your like me, allow me to experiment to get the best possible ride and handling at any given time without expensive and time consuming hardware changes. After experimenting with adjusting the WD at-will and while in motion, I have discovered that that extremely small adjustments can make a world of difference that are only perceptible with instant adjustments. I say this because by the time one stops makes a small adjustment, and gets going again all of the conditions have changed. I use time to measure how much I raise or lower the jacks. For example I can set the app to run for as little as .25 seconds. This allows .001" adjustments under load. It can make the difference between driving 55 or, as I often do, 75 with complete confidence. It took awhile to realize this effect and there was no usable advice out there, except how stupid I am for even saying it. This allows for better handling and safer travel with smaller TV. The traditional wisdom is to have the largest TV possible when in fact a smaller TV works just fine with the correct set up.

|

|

|

11-21-2017, 05:23 AM

11-21-2017, 05:23 AM

|

#35

|

|

"Cloudsplitter"

2003 25' Classic

Houstatlantavegas

, Malebolgia

Join Date: Jun 2007

Posts: 20,000

|

I just don't understand why its rocket science for you and not for me.

Is your set-up so close the the edge that it requires constant adjustment?

Ours is not, once its set for a given load its good to go. A once a Season trip to to the scales has been all thats needed.

But that's just me....I still ware watches I have to wind.

KISS

Bob

__________________

Iím done with ĎadultingíÖLetís go find Bigfoot.

|

|

|

11-21-2017, 06:17 AM

11-21-2017, 06:17 AM

|

#36

|

|

Vintage Kin

Fort Worth

, Texas

Join Date: Nov 2006

Posts: 8,014

|

A VPP highlights TV suspension & steering deficiencies. In a fair amount of isolation versus other types.

Mainly movement of body against suspension. Second is slack in the steering for some vehicles. Last is the way the rig tracks. Which is about shock absorber design, then tires (design) and then tire pressure.

All of these are why the insensitive are so happy with a new TV. General accumulation of wear not corrected. The worse the overall TV design, the more this would be so. (Perceptions).

But I'm having a harder time reconciling 55 versus 75. A description via scale numbers (percent distribution; TT axle split) and tire pressures is really what any of this is about (for a given loading).

Their discovery is what makes it interesting. It's still X1 ranging to X2: the highest versus the lowest loads in combined vehicle weight. And how it breaks out past that (with what changes afford best perceived road manners).

Carry more of the fixed amount in the trailer? (And TV tire pressure change)

Etc

.

|

|

|

11-21-2017, 07:33 AM

11-21-2017, 07:33 AM

|

#37

|

2 Rivet Member

2016 30' Classic

Lexington

, Kentucky

Join Date: Aug 2016

Posts: 48

|

All that will work just as well as it ever did. all i'm saying is there is another way. Remember how well we thought carburetors worked until we were exposed to fuel injection.

|

|

|

11-21-2017, 07:38 AM

11-21-2017, 07:38 AM

|

#38

|

2 Rivet Member

2016 30' Classic

Lexington

, Kentucky

Join Date: Aug 2016

Posts: 48

|

All that will work just as well as it ever did. all i'm saying is there is another way. Remember how well we thought carburetors worked until we were exposed to fuel injection.

|

|

|

11-21-2017, 07:43 AM

11-21-2017, 07:43 AM

|

#39

|

2 Rivet Member

2016 30' Classic

Lexington

, Kentucky

Join Date: Aug 2016

Posts: 48

|

As far as being on the edge, many setups will work just fine, but with some fine tuning, they would work so much better. New 1/2 ton pickups have a capacity that exceeds may 3/4 tons of just a few years ago. I just believe that one does't need a semi to haul a camper. Especially if the TV is a daily driver.

|

|

|

11-21-2017, 08:25 AM

11-21-2017, 08:25 AM

|

#40

|

Rivet Master

1988 25' Excella

1987 32' Excella

Knoxville

, Tennessee

Join Date: Oct 2010

Posts: 5,118

|

You are right, of course. Jack position will tell you everything you need to know. A couple of trips across a CAT scale for the initial calibration and then you can dial in weight restoration to the front.

|

|

|

|

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Recent Discussions

Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|